● High heat transfer efficiency

The heat transfer efficiency is 1-3 times that of the tube heat exchanger, and the heat transfer coefficient can be up to 3300W/m²k.

The heat transfer efficiency is 1-3 times that of the tube heat exchanger, and the heat transfer coefficient can be up to 3300W/m²k.

●Strong running reliability

The unsplit two channels are sealed to ensure that the two working media are not mixed.

● Effective recovery of low-temperature heat energy

The two kinds of working medium in the equipment are exchanged for full reflux heat transfer, suitable for heat transfer of small temperature, heat recovery of waste heat, and full utilization of low temperature heat energy.

● Small resistance

Low pressure loss to handle large volume of steam or gas; Have the self-cleaning brush ability, because its medium is helical flow, dirt is not easy to deposit; It is easy to clean, can be washed with steam or lye, easy to do, suitable for installing cleaning device; The flow rate is higher than that of other heat exchangers.

♦ The nominal pressure Pn is 0.6, 1.0, 1.6 MPa.

♦ The nominal pressure Pn is 0.6, 1.0, 1.6 MPa.

♦ Allowed working temperature: carbon steel for - 20 ~ 350 ℃, the stainless steel is - 50 ~ 380 ℃.

♦ When choosing equipment, the fluid in the equipment channel should be in a turbulent state through proper process calculation (general fluid velocity is greater than 1M/SEC; gas velocity is greater than 10M/SEC).

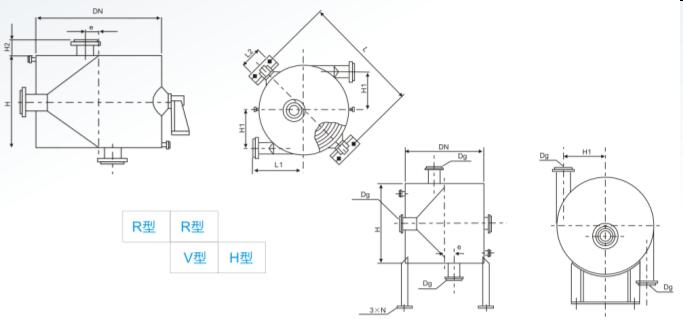

♦ The equipment can lie or stand, but only when used for steam condensing.

♦ The whole heat treatment is applied to the caustic industry to eliminate stress.

♦ When the flow value of the channel is large, the process design can be optimized by using unequal spacing channels.

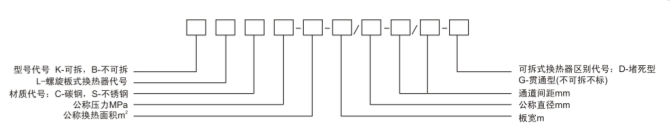

Model representation:

This product only provides the technical parameters of the undetachable spiral plate heat exchanger, which can be designed according to the user's requirements.

Company Tel:

020-86099023 | 86098701 | 86098693

020-86097959 | 86096463 | 86099617

24-hour Serivce Tel:02086099023

24-hour Serivce Tel:02086099023

Address: Jiahe,Baiyun district,Guangzhou